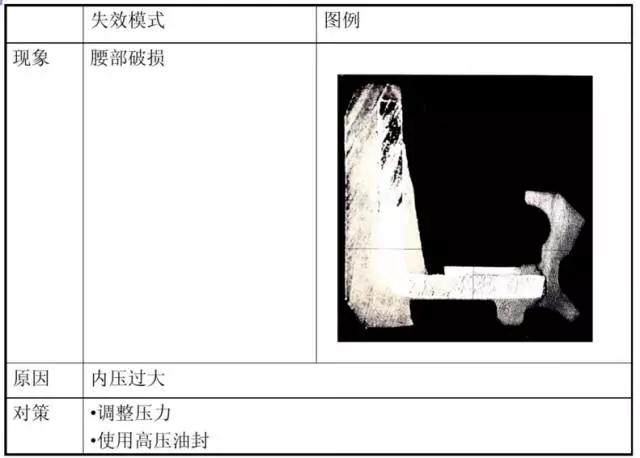

Common causes of oil spills

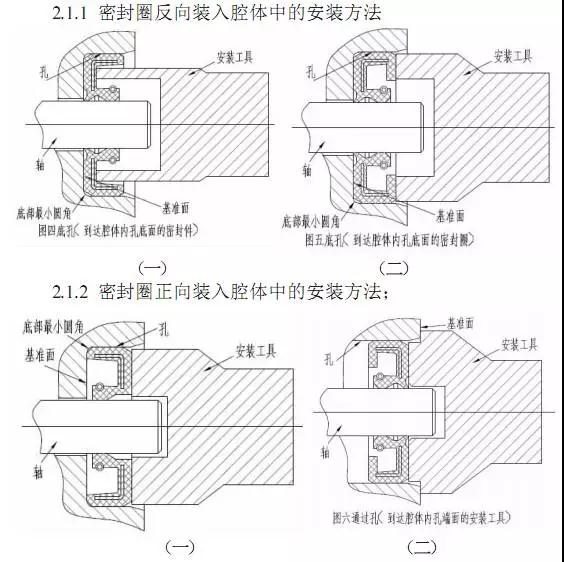

1 Reasons for assembly

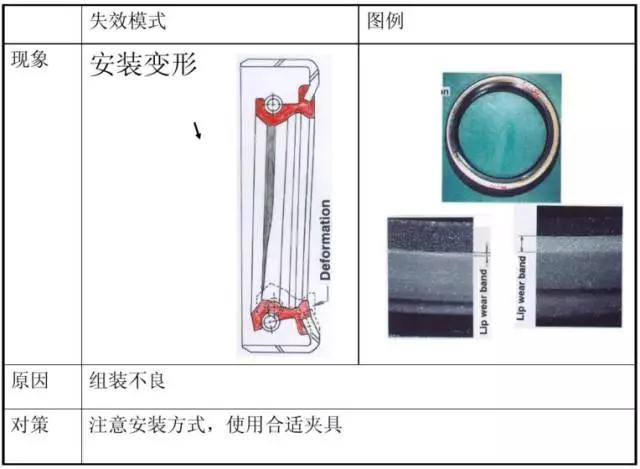

Due to the press-fit tooling, the oil seal is deformed after press-fitting;

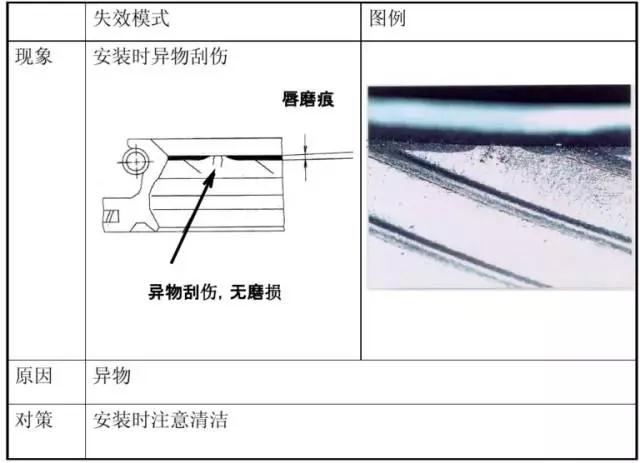

During the assembly process, the oil seal passes through the thread or spline, causing scratches on the lip;

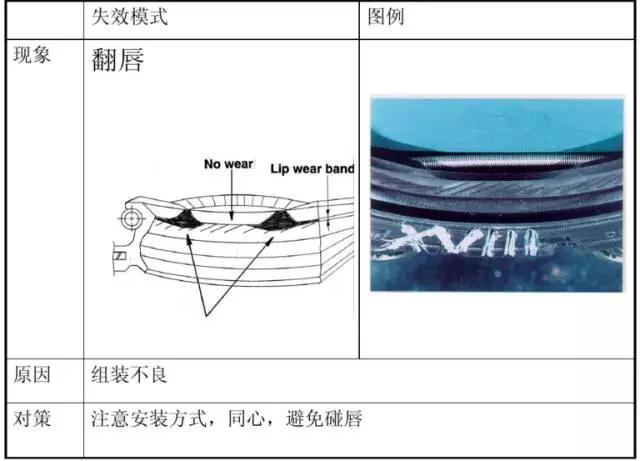

Due to the low roughness of the oil seal and the excessive pressing force, the spring fails or the lip is turned over.

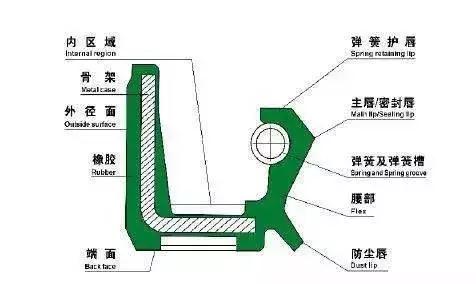

2 skeleton reason

Due to the material and manufacturing problems of the oil seal spring, its performance is invalid.The spring failure form is: the spring is too tight or too loose. When the spring is too loose, the spring compression force is small and cannot achieve the sealing effect. When the spring is too tight, the spring compression force is too large. An oil leak has occurred.

3 Reasons for working medium

The working medium is oil.

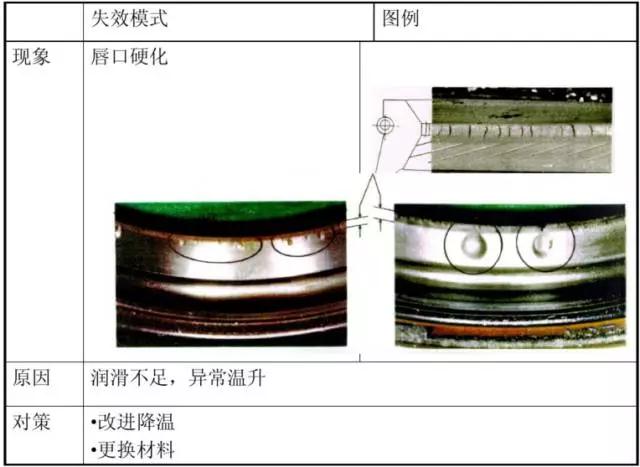

The selection of oil seal material should consider its compatibility with oil. The two have poor compatibility, which will cause lip swelling, hardening, softening, cracking, etc., and eventually oil leakage.

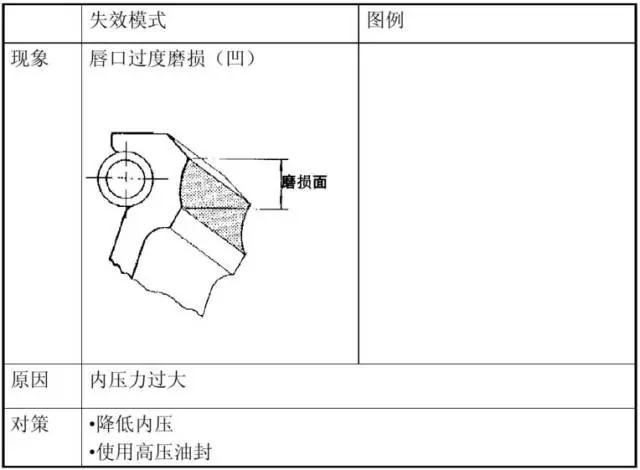

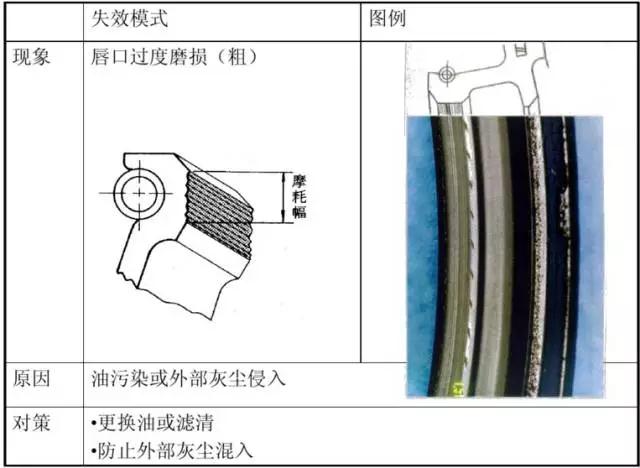

4 Reasons for lip wear

Cleanliness issues: casting sand, machined iron filings, oil impurities, etc., a large amount of oil seal lip parts are accumulated, and abnormal wear occurs during work;

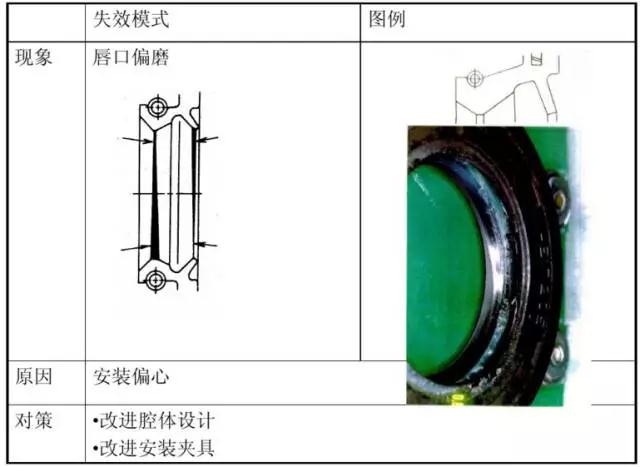

The position of the oil seal and the rotating shaft are not on the same axis, and the eccentric wear occurs after the oil seal is press-fitted, and the lip is abnormally worn;

The lithium-based grease at the oil seal lip is poorly lubricated, and dry friction will occur, resulting in abnormal wear.

Reasons for 5-axis

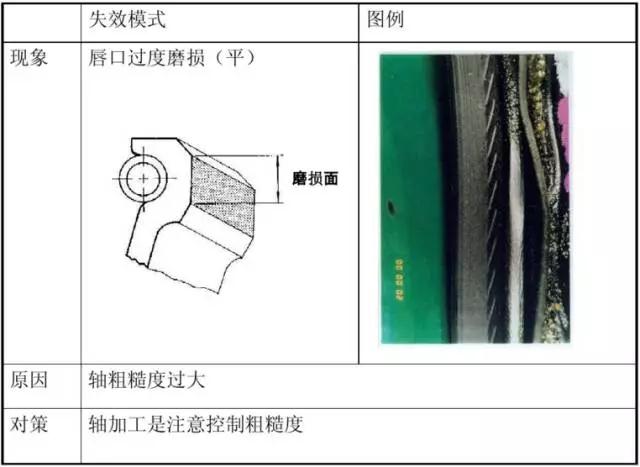

The surface roughness and hardness of the rotating shaft are unreasonable. At present, the automotive industry generally chooses the roughness not less than 0.8, and the parts that cooperate with the oil seal will be high-frequency quenched, and the hardness is not less than HRC55;

There are defects on the surface of the rotating shaft, such as corrosion, scratches, directional knife marks, etc.

solution