1 Introduction

The HJZ series reducer is a special reducer for the roller drive device of the casting and rolling mill. It is a new type of reducer successfully developed by our company based on the transmission principle. It is a major breakthrough in the double planetary gear reducer.

2. Type, characteristics and scope of application

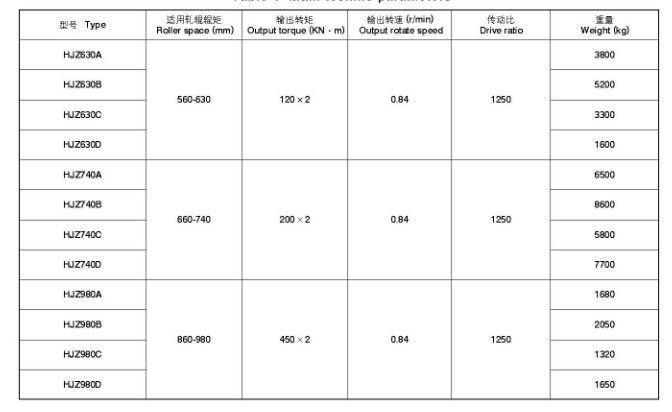

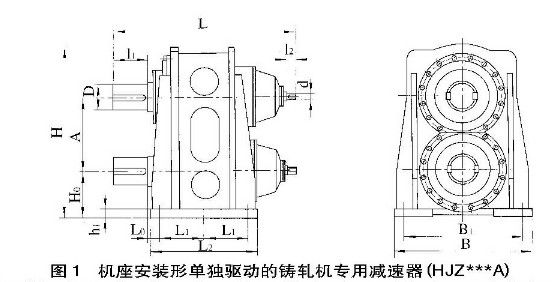

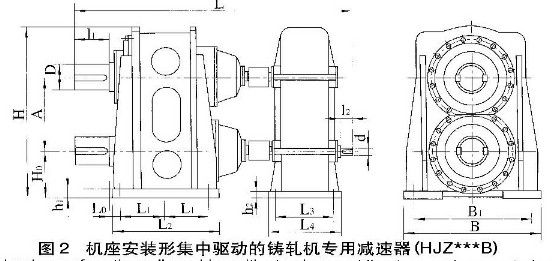

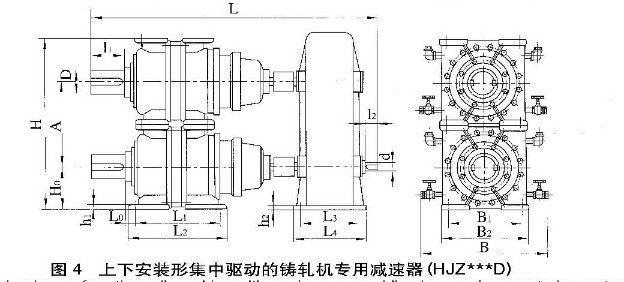

There are two types of special reducers for the roller drive of the casting rolling mill according to the installation form.Namely: base installation type (see Figure 1, Figure 2) and vertical installation type (see Figure 3, Figure 4).There are two types of special reducers for the roller drive of the casting rolling mill according to the driving form.That is, a single drive form driven by multiple motors (without shunt box, see Figure 1 and Figure 3) and a centralized drive form driven by one motor (see Figure 2 and Figure 4 with shunt box).The separate drive type transmission device of the special reducer for the casting and rolling mill is simple.The roll speed is controlled by an electrical device and can be used for casting and rolling mills with different roll diameters and different roll speeds. , The centralized drive type transmission device has more shunt boxes than the single drive type, which replaces the electrical control device of the single drive type.In consideration of economic indicators, a separate drive type transmission is preferred.The single drive mode and the centralized drive mode of the special reducer for the casting-rolling mill are suitable for the rolling working state of any casting-rolling mill.For cast-rolling mills whose rolls are in a worn state during work, a separate drive type special reducer for cast-rolling mills can ensure the same roll speed by adjusting the motor speed, so as to ensure the surface quality of the rolled workpiece.The separate drive mode can be used not only for rolls of the same diameter, but also for rolls of different diameters (not only for diameter wear).The centralized drive mode is only suitable for casting and rolling mills with the same roll diameter. When the product surface quality is required to be high, the roll diameter can only be modified to ensure the roll speed.

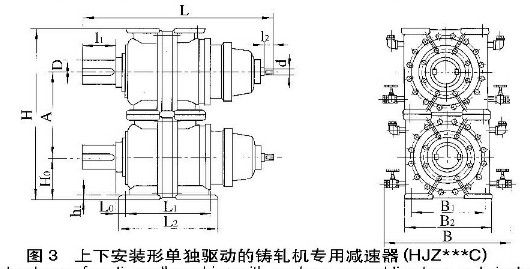

3. Main technical parameters

The main technical parameters of the special reducer for the casting and rolling mill are shown in Table 1.

4. Shape and installation dimensions

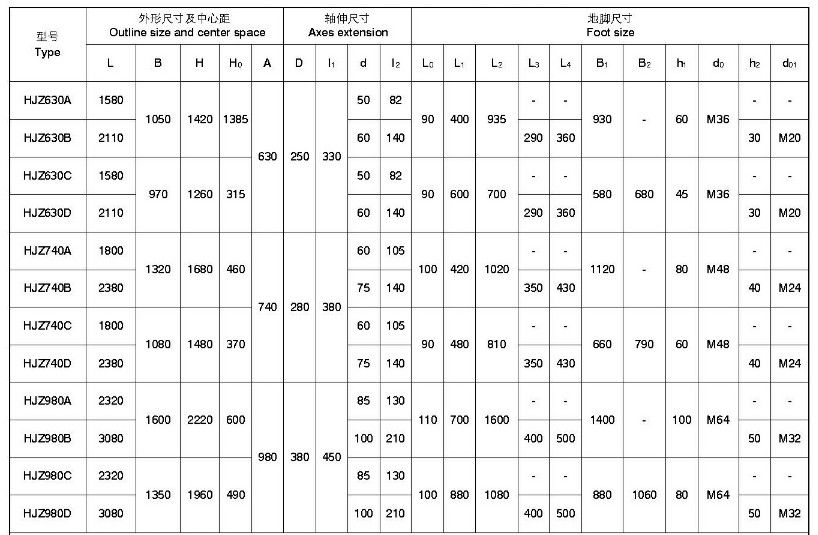

The overall installation dimensions of the special reducer for the casting and rolling mill are shown in Table 2.

Table 2 Shape and installation size

5. Selection method

The selection method of the special reducer for the casting-rolling mill is based on the roll center distance of the casting-rolling mill, the required rolling torque of the rolls and the rotation speed of the rolls.

例.有一轧辊中心距为960mm的铸轧机,轧螺丝所需的轧制力矩是2×400kN.m轧辊转速0.84r/min。查表1.则选择HJ2980传动装置。

6. Installation, use and maintenance

The connection between the reducer in the transmission device and the motor and the working machine should be elastic coupling, gear coupling or other non-rigid coupling.And make careful adjustments to ensure assembly accuracy.

It is strictly forbidden to blow or impact the assembly to prevent damage to seals, retaining rings, bearings and other parts.

Before the reducer in the transmission device is put into use, it is necessary to check whether the reducer is filled with the required lubricating oil. In any case, the oil level of the reducer cannot be lower than the lowest position of the oil standard.

The installed reducer must be tested before being put into use.Run idling for 2h before load test.Start the load test under normal dry running conditions.When conditions permit, it should be loaded gradually in the following four stages:

The first stage is 25% of the rated load

The second stage is 50% of the rated load.

The third stage is 75% of the rated load.

The fourth stage is 100% of the rated load.

When it is impossible to gradually load the site conditions, at least 2 hours of idling and 4 hours of full load operation must be carried out.

Special reducer for casting and rolling mill adopts oil pool lubrication.When the reducer is used for the first time, the lubricating oil must be replaced after 300-600h of operation.Drain the lubricating oil when the lubricating oil is not cold after the reducer is stopped.After that, the reducer is replaced every time it runs for 1500-5000h, which is mainly determined by the working environment.However, the interval between lubricating oil changes should not exceed 18 months.The reducer should be replaced with lubricating oil of the same grade, and lubricating oils of different grades or produced by different factories must not be mixed together.