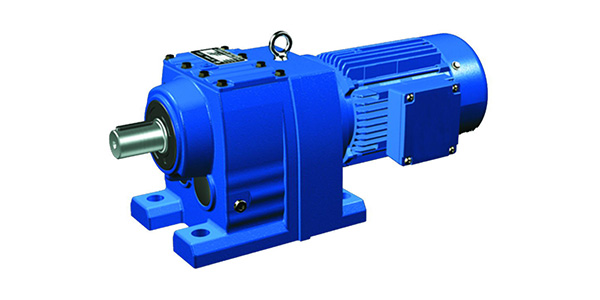

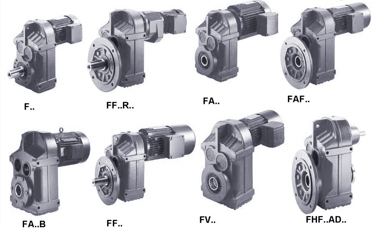

Power/input power:0.12~160kW

Torque/torque: 40~18000Nm

Speed ratio/gear ratio: 1.30~21545

Output shaft type/output type: solid shaft

Installation method/installation type: foot type, flange

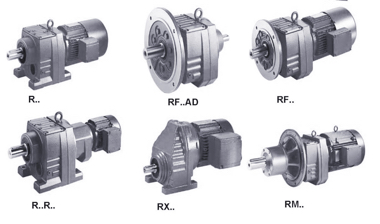

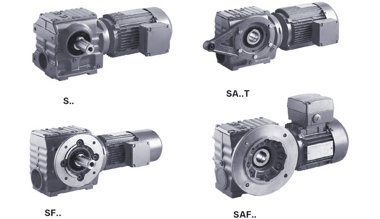

Power/input power:0.12~200kW

Torque/torque: 150~50000Nm

Speed ratio/gear ratio: 5.93~17312

Output shaft type/output type: solid shaft, hollow shaft (flat key, spline, shrink disk)

Installation method/installation type: foot type, flange, torque arm

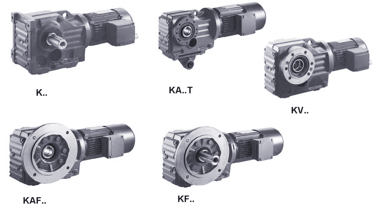

Power/input power:0.12~200kW

Torque/torque: 90~18000Nm

Speed ratio/gear ratio: 4.18~19526

Output shaft type/output type: solid shaft, hollow shaft (flat key, spline, shrink disk)

Installation method/installation type: foot type, flange, torque arm

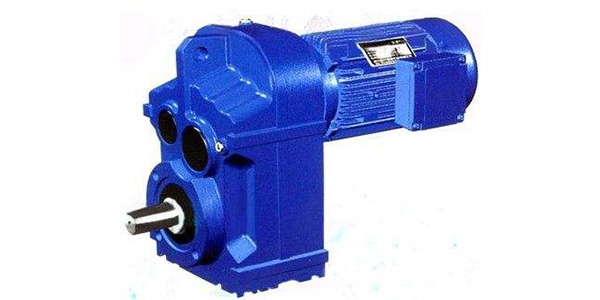

Power/input power:0.12~22kW

Torque/torque: 43~4000Nm

Speed ratio/gear ratio: 7.00~11501

Output shaft type/output type: solid shaft, hollow shaft (flat key, spline, shrink disk)

Installation method/installation type: foot type, flange, torque arm

Power/input power:0.12~315kW

Specifications/Specifications: 63~400

Number of poles / number of poles: 2,4,6,8, 2,4,6,8, XNUMX, XNUMX poles and variable frequency drive \ XNUMX, XNUMX, XNUMX, XNUMX or frequency conversion

Product Highlights

The product follows the modular and optimized design concept, uses finite element analysis technology, and adopts a unique low-noise gear tooth profile design to ensure the advanced nature of the design

The transmission ratio is finely graded and has millions of different combinations to meet the different needs of users

From the selection of materials to the manufacturing, we are strictly controlled-precision casting of the box body, beautiful and firm, carburized and hardened gears, and durable

Processed with FMC flexible manufacturing unit to achieve high precision and maintenance-free products

The reducer has foot installation, flange installation, torque arm installation, etc.

The output methods are solid shaft, hollow shaft, and can choose to add single key, spline or lock disk connection

Package appearance scheme

According to different materials, packaging can be divided into carton packaging and wooden box packaging.The new packaging solution includes company brand information, packaging information, transportation and storage specification information, detailed product information, and product selling point information.

Packing specification division

According to the weight of different products, the packaging specifications are divided into: carton packaging, carton packaging + pallet, wooden box + pallet, large carton + small carton + pallet, multiple carton boxes + pallets, and multiple wooden boxes for stacking.

Packing and transportation

The packaging can be transported by stacking cars or containers

Packaging storage method

Packaging shells are stacked directly or placed on shelves

solution

Communications industry

Communications industry

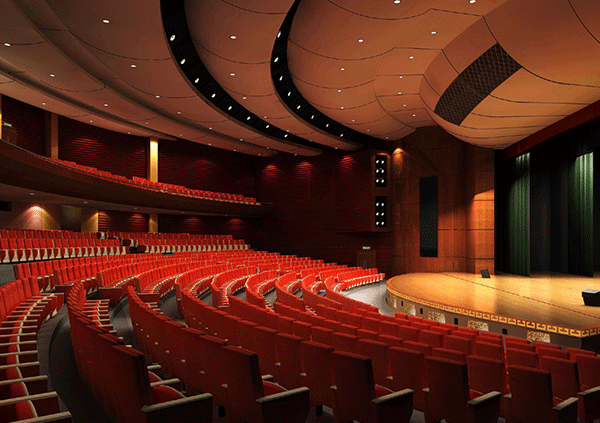

Stage machinery

Stage machinery

Metallurgical industry

Metallurgical industry

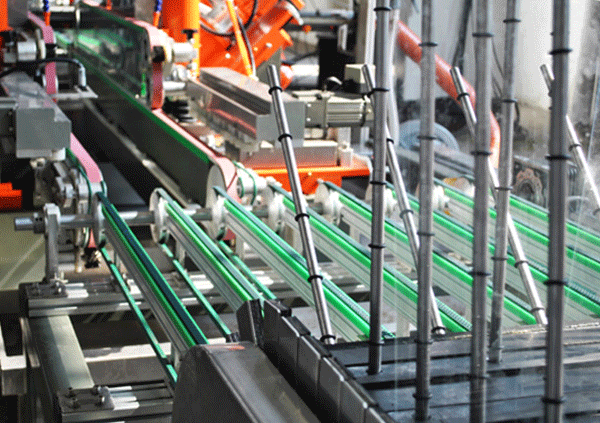

Glass machinery

Glass machinery