<XNUMX> Overview:

This product is based on the People’s Republic of China Metallurgical Industry Standard YB/T050-93 "YNK Gear Reducer for Metallurgical Equipment". It is a four-stage parallel shaft hard gear optimized and designed by the company’s reducer technology center with decades of superb technology. Face cylindrical gear reducer, product quality is stable and reliable

<XNUMX>, the scope of application

1 The input speed is not too high at 1500 rpm.

2 The peripheral speed of the gear drive is not more than 20 meters per second.

3工作环境为-40-+45℃。如果低于0℃,启动前润滑油应预热至0℃以上。

4Widely used in metallurgy, mining, chemicals, building materials, lifting, transportation, textile, paper, food, plastics, rubber, engineering machinery, energy and other industrial sectors.

<Three>, performance characteristics

1.The speed ratio range of the reducer is large: 100-500.

2 High mechanical transmission efficiency: greater than 91%.

3 gears are made of high-quality alloy steel by carburizing, quenching and finishing.

4Small size, light weight, high precision, large carrying capacity, high efficiency, long life, stable transmission and low noise.

5- Generally use oil pool lubrication and natural cooling. When the thermal power cannot be satisfied, circulating oil lubrication and cooling coil cooling can be used.

6 Easy to disassemble and inspect, easy to install.

<XNUMX>, reducer specifications and their representation

1 Specification: 395,440,497,555,620,705,790,880.995,1110,1240,1400,1570,1760

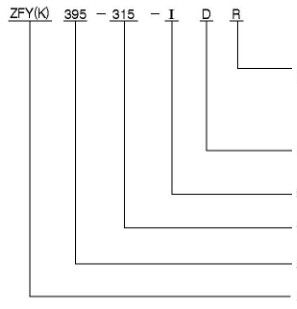

2 Representation method:

R: Rotation of the output shaft (viewed from the output shaft)

R-clockwise

L.Counterclockwise

T.Two-way rotation

TR-two-way rotation, the main rotation is clockwise

TL-two-way rotation, the main rotation is counterclockwise

D: Cooling method

Omitted-natural cooling

B- with cooling coil

D-Circulating oil cooling

I: Assembly type

315: Nominal transmission ratio

395: Specifications (total center distance of cylindrical gears on the midpoint surface)

ZEY(k): Series code: K indicates that the output shaft is a hollow shaft

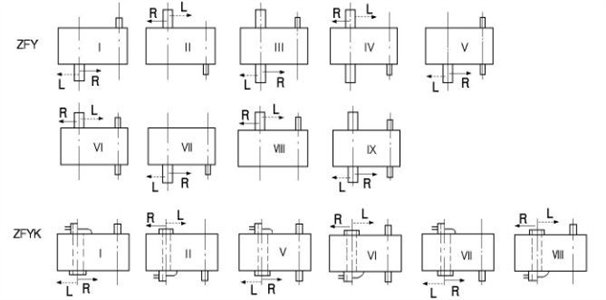

<XNUMX>, assembly type

<six>, work machinery load classification

The load of the driven working machinery can be divided into: uniform load (U), medium impact load (M), strong impact load (H), and 24h continuous working conditions, see Table 8 (the load symbols listed in the table) , After the details of the working condition of the working machine are given, it can be corrected).

<XNUMX> Selection method:

1 Known parameters and conditions:

The name of the prime mover: power P,

Working machine name: Power P2

The required transmission ratio i=n,/n2

kW, speed n,

kW, speed n.

One min

r / min

Working hours per day h: number of starts per hour; operating cycle per hour %;

Load characteristics (stable, impact, strong impact); reliability requirements (general, high, high).

Ambient temperature ℃; site heat dissipation conditions; cooling water temperature ℃.

Coupling type, whether there are other additional forces on the shaft extension of the gear shaft,

Assembly type; output shaft rotation direction (please specify the main rotation direction when rotating in both directions)

Are there any other special requirements

2Select specifications and models according to rated power

The rated power PN (table 10) of the reducer is stable according to the load, the working time is less than or equal to 10h per day, and no more than 5 starts per hour.The allowable starting torque is 2 times the working torque, and it runs in one direction. The safety factor of contact strength of a single pair of gears is 1.The probability of failure rate is less than or equal to 1% and other conditions are calculated and determined.When the reducer is running in both directions, it is necessary to multiply PN by a factor of 0.7-10 depending on the situation. When the reverse load is large, the reversing frequency is frequent, and the selected reliability kR is low, the factor should be smaller, and vice versa.

The rated power of the selected reducer must meet: Pc=P2KAKsKR≤PN

In the formula, Pe is calculated power and P2 is working machine power kA usage coefficient, see Table 1

K.A start-up coefficient, see table 2 KR a reliability coefficient, see table 3

3 Check according to allowable thermal power

减速器的许用热功率R适用于环境温度20℃,每小时100%连续运转和功率利用率(P2/PN100%)为100%

If the conditions are different, corrections must be made.

The selected reducer should meet: Pct=P2KtKwKP

Where Pct-calculated thermal power

Kw-operating cycle coefficient, see Table 5

4 Check the radial load on the shaft extension

K.One ambient temperature coefficient, see Table 4

K, a power utilization factor, see Table 6

The radial load Fr borne by the intermediate part of the input shaft and output shaft of the reducer should be lower than the value in Table 7

Nine, installation, use and maintenance

1 The axis of the input shaft and output shaft of the reducer, as well as the axis of the connecting part, should be coaxial, and the error should not be greater than the allowable value of the coupling used.

2 After installation, the required lubricating oil must be injected into the oil sump of the box body, and the oil level should be at the height between the upper and lower engraved lines specified by the oil dipstick.

3 The reducer must be turned by hand before it is officially used, and it must be flexible and free from jamming.Then carry out no-load operation for no less than 2 hours.The operation should be stable, and there should be no shock, vibration, noise, or oil leakage. If any fault is found, it should be eliminated in time.

4 When the new reducer is used for the first time, it must be replaced with new lubricating oil after 20 days of operation.In the future use, the oil level should be checked regularly.If it is lower than the specified height, make up in time.Under normal circumstances, the oil must be changed every three months for the reducer that works continuously for a long time, and the oil must be changed every six months for the reducer that works less than eight hours a day.

5 oil selection

环境温度:-10℃-0℃时用L-CKC68-L-CKC100(原N68-N100)润滑油

0℃-40℃时用L-CKC100-L-CKC320(原N100-N320)润滑油

6 When it is found that the oil temperature rises significantly during use, the temperature rise exceeds 60°C or the oil temperature exceeds 85°C, or abnormal noise occurs, stop using it and check the cause.If it is caused by tooth surface glueing, etc., it must be repaired, troubleshooting, and the lubricating oil replaced before use.

7 If severe oil leakage or oil leakage is found on the joint surface during use, open the machine cover and apply 601 sealant. If oil leakage is found, please replace it according to the crude oil seal model.